As one of the country’s leading players in precision mold-making, Lap Phuc Co., Ltd., based in Phu Thuan ward, Ho Chi Minh City, has set a growth target of 20%–30% compared to 2025. Thanks to sustained investment in advanced technologies over many years and continuous improvements in the skills of its engineers and workers, Lap Phuc’s mold products are now highly competitive in both price and quality against those from other regional markets.

|

|

|

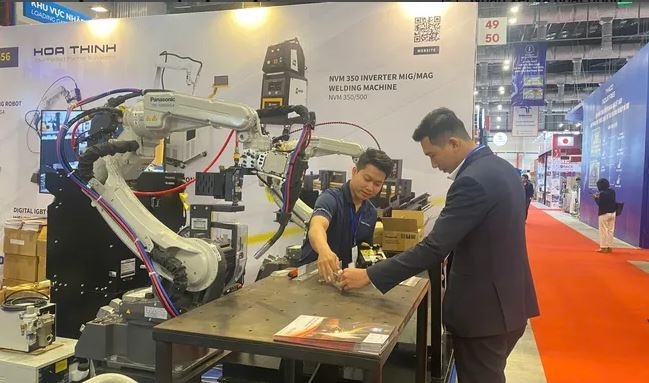

Visitors to the Vietnam Supporting Industry Fair in Ho Chi Minh City (Photo: sggp.org.vn) |

U.S. importers are currently prioritizing the company’s products, and its orders for 2026 remain relatively stable, shared Nguyen Van Tri, General Director of Lap Phuc Co., Ltd.

In the mechanical–electrical sector, Le Mai Huu Lam, General Director of Cat Van Loi Industrial Electrical Equipment Manufacturing JSC, has set a growth target of 23%. To achieve this goal, the company plans to strengthen internal capabilities, with human resources identified as the decisive factor. At the same time, Cat Van Loi is pursuing additional international certifications to participate in major projects at home and abroad, while stepping up trade promotion to help Vietnamese products reach wider markets.

Thanks to its standardized production aligned with international norms, the company’s mechanical–electrical products have been deployed in major domestic projects such as Metro Line No.1 (Ben Thanh–Suoi Tien), Long Thanh International Airport, Van Phong 1 Thermal Power Plant, and the National Data Center. Internationally, the company has supplied projects including the Malina Metro Line in the Philippines, Cambodia’s Techo International Airport, and the Matarbari coal-fired power plant in Bangladesh.

Although many Vietnamese mechanical–electrical products already meet European and Japanese standards and supply foreign partners, local enterprises note that they still face barriers to participating in large-scale domestic projects. Tran Thanh Trong, Vice Chairman of the Ho Chi Minh City Mechanical–Electrical Enterprises Association, emphasized that domestic firms are fully capable of providing auxiliary system installations for urban railways, including power supply systems, backup generators, ventilation, peripheral automation controls, fire prevention systems, and elevators.

He stressed that alongside investment in technology, process standardization, and high-quality workforce development by enterprises, state management agencies should give greater consideration to prioritizing domestically produced goods and services in urban railway projects. This will help reduce investment and operating costs, enhance national self-reliance, and lay the groundwork for the development of a modern Vietnamese railway industry. For components that must be imported, clear roadmaps for technology transfer in production, operation, and maintenance should be required.

According to Tri, access to capital remains a major challenge, as investment demands are high while lending interest rates remain elevated. Although Ho Chi Minh City is implementing stimulus loan programs, not all enterprises can access them. In addition, industrial land rental costs are rising sharply, with prices in Cu Chi Industrial Park reaching around 250 USD/sq.m for a 50-year lease, eroding manufacturers’ competitiveness.

Survey results among industrial enterprises in the city indicate strong confidence going into the first quarter of 2026. Specifically, 32.8% of firms expect conditions to improve, while 73.5% of state-owned enterprises assess their business outlook for Q1-2026 as more positive.

Source: VNA